WARP KNITTING TECHNOLOGIES

Knitting Innovation Through Software-Driven Design Solutions

A Transformative Leap in Textile Innovation

With unmatched flexibility in rapid prototyping, design precision, and quality manufacturing, Shawmut leads the way with the world’s most advanced digitally controlled warp knitting, warp prep, and fabric prototyping systems through our family company, Shawmut Infinite.

Shawmut Infinite marks a transformative leap in textile innovation, blending cutting-edge technology with over 50 years of warp knitting expertise. We can move from digital design to physical samples in days, not weeks, cutting development time by 90%. Large sample MOQs, sample waste and low yields are a thing of the past.

Our in-house vertical integration from the fabric design to warping, knitting, dyeing, finishing and lamination ensures your project will go as smoothly as possible.

Warp Knitting Applications

LEARN MORE

LEARN MORE

LEARN MORE

LEARN MORE

LEARN MORE

LEARN MORE

Contract Fabrication Challenges We Solve

Are you ready to upgrade or reshore your medical component or device manufacturing?

- Collaborative process with customer designers and product teams

- Ability for the product or material to tell the customer’s story

- Product development engineering

- Small scale R&D production capabilities

- Certified materials testing labs

- Sustainable solutions and recyclability

- Environmental cycle testing

- Precision color matching

- Re-shoring of material and device development

- Re-shoring of manufacturing and assembly

- North America supply chain of raw materials

- Lower freight and transportation costs

- Rapid response supply chain timeline

- Small-scale development and prototyping runs

- In-house certified testing labs

- Over a century of advanced materials expertise

- Moisture and UV barrier

- Controlled breathability and/or moisture vapor transfer

- Elasticity, controlled elongation and stretch for supreme adaptability

- ASTM 1670/1671 for blood and blood-borne pathogen protection

- Thin barrier film expertise

- Durable protective properties through the rigors of numerous launderings and critical end-use applications

- Drapability for comfort and appearance

- Sustainable production

Warp Knitting Capabilities

- Concept Development and Fabric Design

- Wide Array of Fine Denier Filament Yarns

- Rapid Pattern Development and Prototyping

- Digital Control Process

- Remote Customer Design Collaboration

- Real-Time Online Sharing of New Fabric Designs

- Rapid Iterations and On-The-Fly Adjustments

- Minimal Raw Material Used in Prototyping

- Advanced Tricot Warp Preparation Technologies

- Digitally Controlled High Speed Warp Knitting

- Multiple Beam Sizes

- High Accuracy Reduces Rework and Improves Quality

- Multiple Dyeing and Finishing Options

- Small-Batch Dyeing and Finishing

Warp Knitting Featured

Solutions

Learn more about the benefits of Shawmut’s digitally controlled knitting technologies.

Rapid Textile Design and Prototyping

Rapid Textile Design and Prototyping

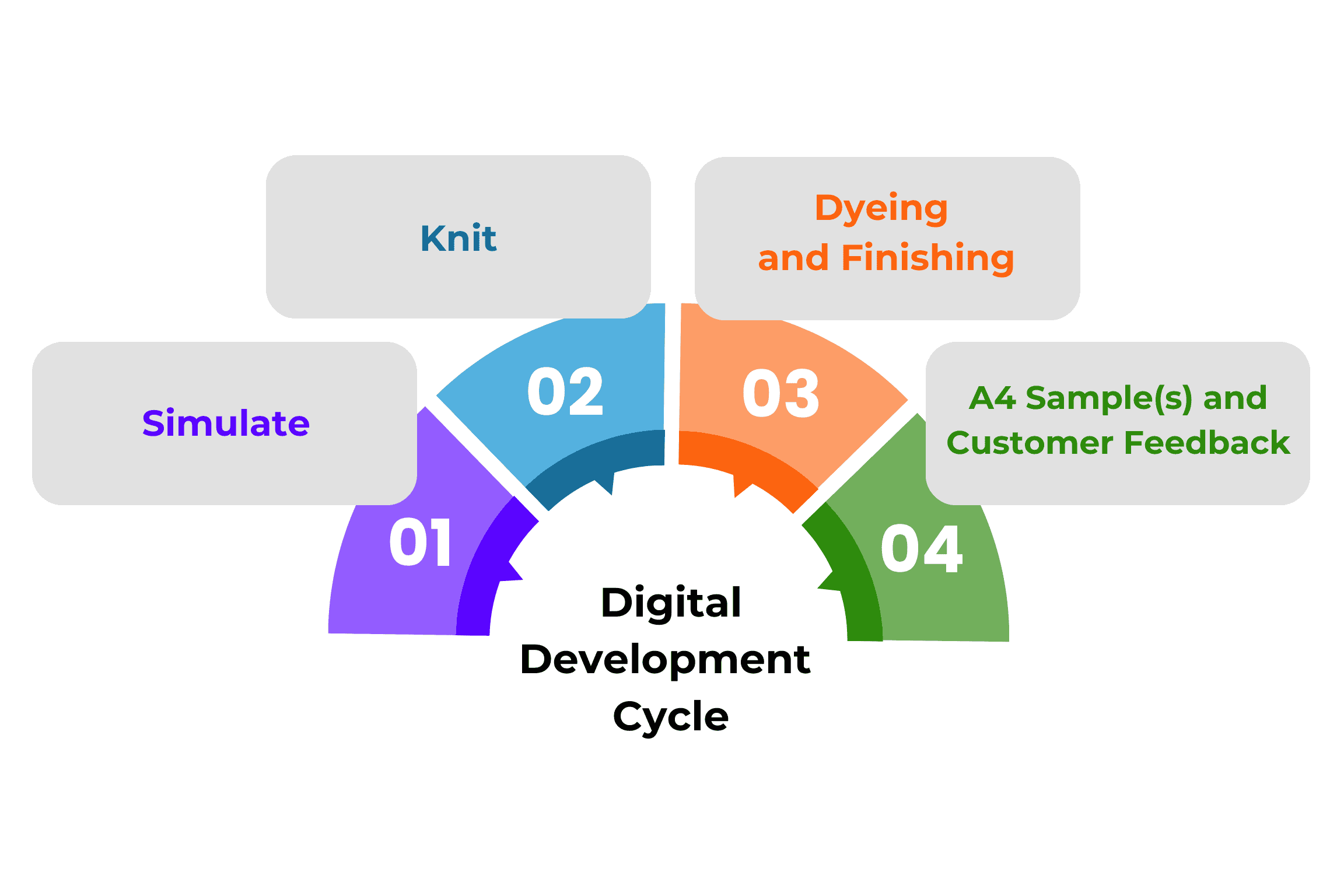

With the advanced knitting and warping services of Shawmut Infinite, we are poised to speed up your development cycles and help you take innovative products from concept to production faster than ever before.

The process starts with our in-house textile designers and engineers after establishing your production needs. We can design patterns digitally, simulate visual options, and send you software-generated simulations instantly online.

Once patterns are reviewed with you, we proceed with small-lot production of multiple patterns developed and changed digitally on the fly – all within one short sample roll – that can be finished in a lab line, and samples shipped within a matter of days. Large MOQs, sample waste and low yields are a thing of the past.

Dyeing and Finishing Options

Dyeing and Finishing Options

From digital to physical to customer-ready.

With finishing at Shawmut Corporation’s adjacent Park Avenue lab, we produce fast, accurate prototyping with small-scale tenter frame finishing and small-lot dyeing and finishing that produces A4-sized swatch samples within days.

This combination of agility, speed, and accuracy supercharges your product innovation cycle.

Once your production is ready for scale, we can dye and finish up to 210” wide, with dyed fabric finished and lab-tested to achieve your target properties (width, weight, etc.). Additional parameters such as pre-tensioning and heat setting ensure stability in future processing steps.

Digital Warp Knitting

Digital Warp Knitting

Our large array of digital warp-knitting technology allows for rapid pattern development and prototyping through a digital control interface. We have the ability to knit between 168-210” in width, with 2-bar, 3-bar, and 4-bar capabilities.

Our latest knitting technology is digitally controlled, no longer using manual setups and mechanical pattern wheels. These state-of-the-art machines run faster, with smoother motion, greater repeatability, and improved quality, and allow pattern changes at the touch of a button.

With precision digital control, we can fine tune elasticity, control elongation and stretch for supreme moldability, while also incorporating sustainable solutions and recyclability into your project.

Advanced Warp Preparation

Advanced Warp Preparation

We specialize in warping a wide range of fine denier filament yarns across key categories. We work with a variety of synthetic yarn types, including nylon, polyester, polypropylene, and more. Our expertise spans a range of yarn textures and conditions, such as FDY, DTY, mono, blended, and bi-component yarns. We also support a broad range of yarn sizes, from fine to coarse filament counts.

Our warp preparation operation contains four tricot warpers, running full-size tricot beams that can be output in multiple sizes.

This exciting rapid design and development capability brings unique value to our customers, growing Shawmut’s position as a preferred innovation partner to automotive and industrial designers around the world.