Filtration Industry

Liquid and Air Filtration Solutions

Innovative Textile Technologies

Shawmut creates filtration media for both liquid and air applications.

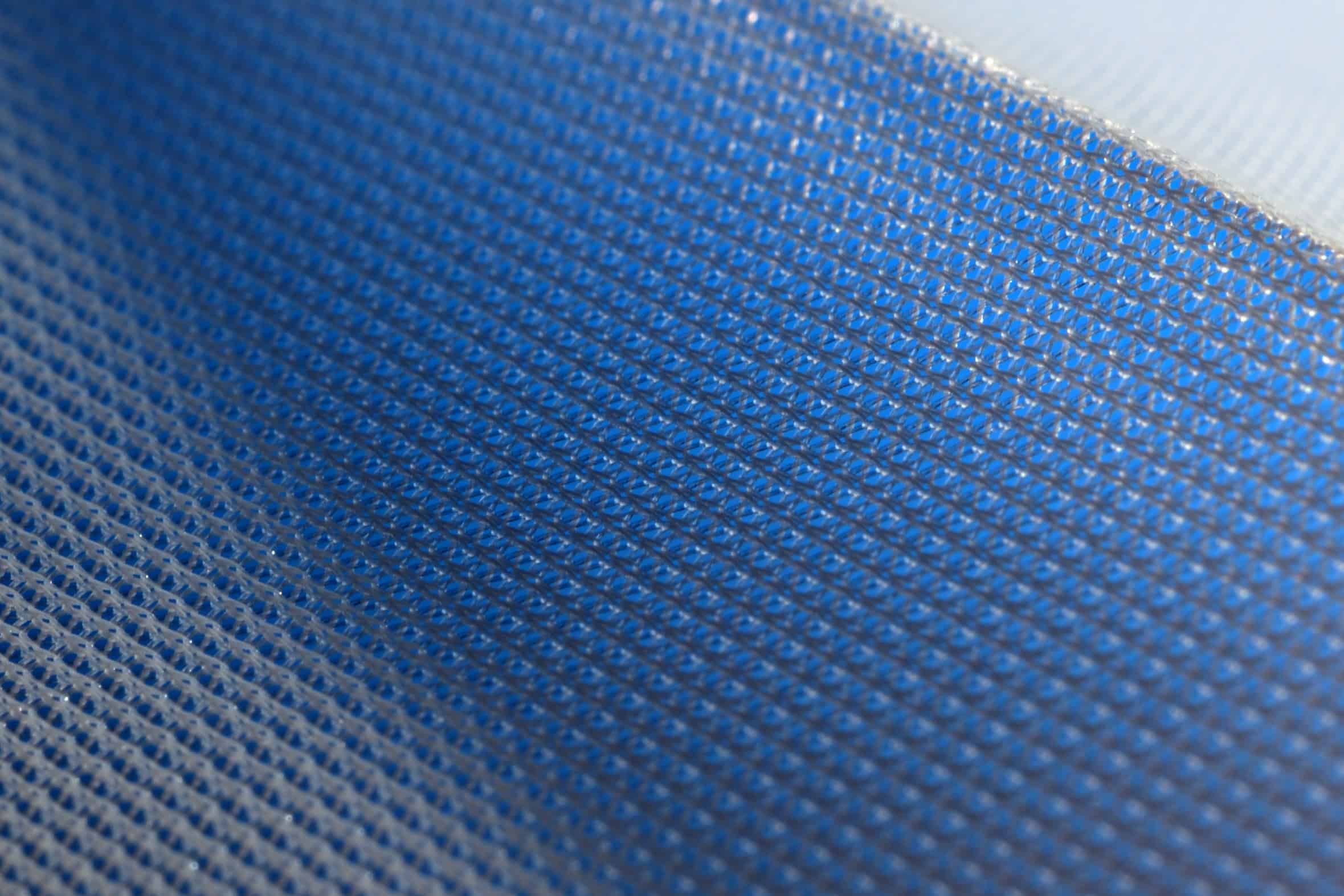

Shawmut is proud to be part of the worldwide push for innovative textile water filtration technologies as a producer of technical fabrics used as permeate carriers for a wide range of reverse-osmosis filtration processes and high PH configurations, and many other liquid filtration needs.

Our custom-formulated meltblown air filtration media is produced in-house using the world’s most advanced process technology and is exceptionally efficient for its weight and thickness.

Filtration Industry Applications

LEARN MORE

LEARN MORE

LEARN MORE

LEARN MORE

LEARN MORE

LEARN MORE

We create solutions to your production challenges

Helping Solve Global Clean Water Shortages with Textile Technology

We specialize in manufacturing Permeate Carrier Fabric to meet your precise specifications, ensuring a filtration solution that aligns perfectly with your needs.

Fabrics Engineered to Solve Hard Problems

Our collaborative process with customer product teams, along with our rigorous engineering and testing processes, ensures the product you need is the product you get.

Elevating Filtration through Unmatched Efficiency

Shawmut MB™ is a meltblown filter media other mask manufacturers are coming to us to make for them due to its high filtration properties, low air resistance, and lightweight.

Global Vertical Integration Produces a Superior Product

Our vertical integration from fabric design, through engineering, knitting, finishing, testing, and slitting ensures well-managed and targeted results.

How can we help you solve your most pressing filtration materials challenge?

Filtration Industry Capabilities

- Made-in-the-USA Reverse Osmosis Permeate Carrier Fabrics

- Custom Fabric Formation

- Bi-Component Yarn Knitting

- Custom Finishing

- Microfiltration, Nanofiltration, Ultrafiltration and Reverse Osmosis Applications

- Water Purification, Desalination and Treatment Applications

- Food, Beverage and Pharmaceutical Processing Applications

- Made-in-the-USA Melt Blown Fabrics

- Custom Meltblown Manufacturing

- Meltblown up to 68” Wide

- Slitting to Custom Widths

- Diecutting

- Respiratory Protection Applications

- HVAC Applications

- Insulation Applications

Filtration Industry Featured

Solutions

Explore in more detail our liquid and air filtration solutions.

Permeate Carrier Fabrics

Shawmut RO-Flow® Permeate Carriers

Our patented high-performance reverse osmosis permeate carrier fabrics are custom designed and engineered for maximum channel integrity. Click here to see more.