You need to trust your PPE, medical, and safety products every time you put them on and use them. We put that trust into every health and safety product we make, and it starts with US-sourced materials and products engineered and manufactured in the US.

In addition to its Protex™ lines of N95 respirators and AAMI-level PPE gowns, Shawmut is a supplier of woven, knit, and laminated medical fabrics for critical OEM medical applications such as medical gowns, DVT prevention devices, and a host of technical fabric solutions in the healthcare and personal safety space.

Respirator fit comparison study shows that many popular N95 respirators do not meet the ASTM F3407 Respiratory Fit Capability standard.

Whether it’s a specific color with a functional texture, or a breathable, autoclavable viral barrier with a sleek technical look, Shawmut brings complex design visions to life.

Shawmut's innovative solution revolutionized protective textiles by laminating metalized film with a fire-retardant nonwoven.

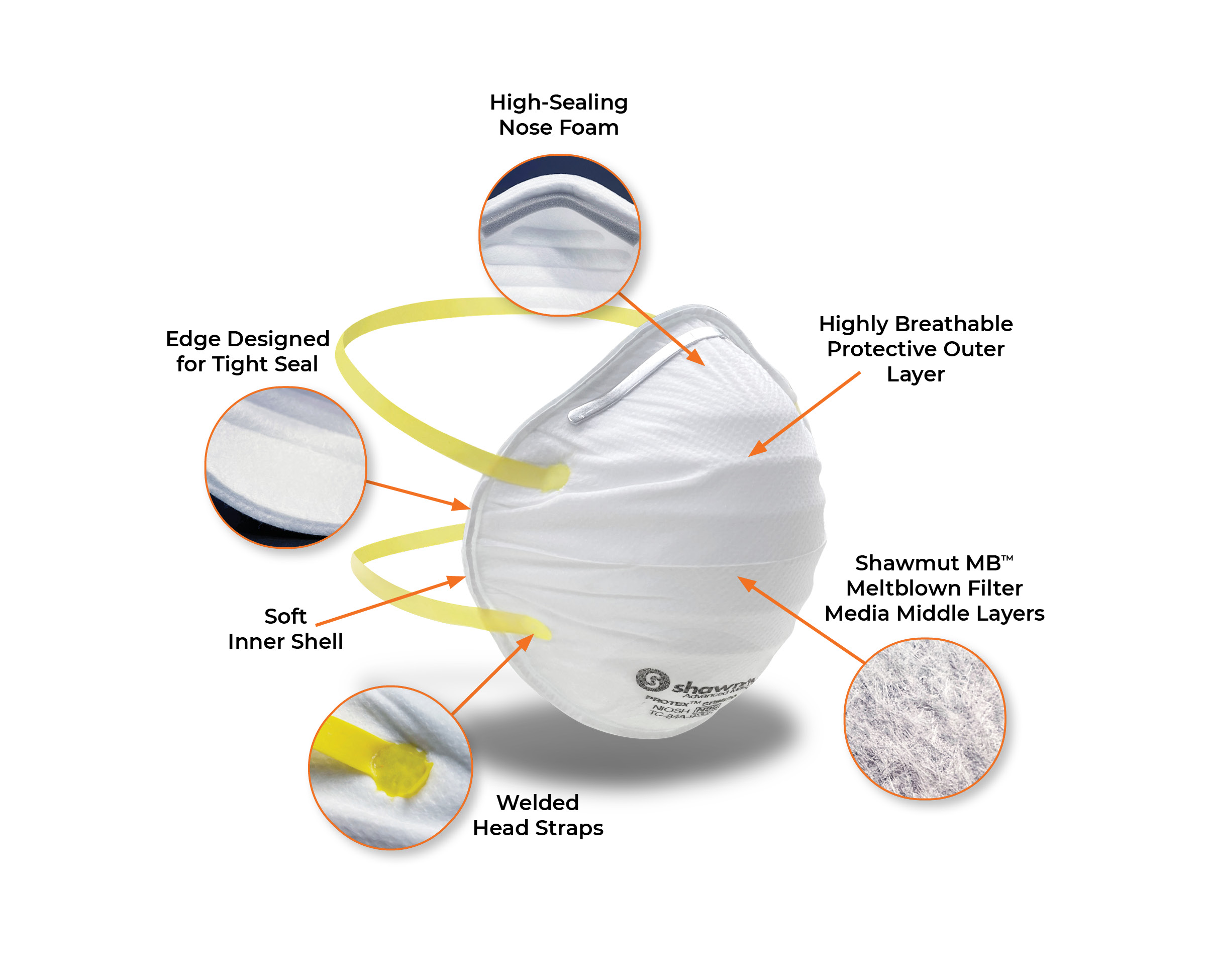

Shawmut MB™ is a meltblown filter media other mask manufacturers are coming to us to make for them due to its high filtration properties, low air resistance, and lightweight.

How can we help you solve your most pressing health and safety materials challenge?

Shawmut Corporation

Global Headquarters

208 Manley Street

West Bridgewater, MA 02379

USA

Industries Served

Capabilities

About Us

Brands

More

Legal