If an N95 and a KN95 both have 95% filtration capability, they can both protect you equally, correct?

And any N95 can protect as well as any other N95, right?

Not so fast.

The ability of an N95 respirator (or any other filtering facepiece, for that matter) to protect you not only depends on how good the filtration level is, but also how well it seals around your face (commonly referred to as “fit”).

If an N95 can’t seal well, your breathing can go around the edges of an N95, and not through the filter part of the mask. Airborne particles can more easily get into your nose and mouth, and vice versa.

Over the last 20 years, several studies found that a high number of NIOSH-approved respirators on the market didn’t fit and seal the vast majority of users. In 1995, when NIOSH put the current N95 regulations into operation, no evaluation of the fitting characteristics of a particulate respirator was included.

Many companies that require their employees to wear N95s and other filtering facepiece respirators, both reusable and disposable, are directed by OSHA to annually fit test their employees to find a respirator on the market that seals well against their skin for maximum protection. Within a company, this is part of their employee respiratory protection program. Users of respirators outside of corporate respiratory programs, such as DIY-ers trying to protect against sanding dust or paint overspray, generally have no access to fit testing and don’t really know how well their chosen model fits to their skin.

Respirators that don’t fit the majority of users can really complicate a respiratory program. It requires companies to stock many different respirator models and sizes so that their entire workforce is equipped with a well-fitting respirator. As a result of the respirator fit findings, or lack thereof, NIOSH used ASTM International to develop the ASTM F3407 – 20 Standard Test Method for Respirator Fit Capability. The Standard generates a fit capability score by using tests subjects in a calibrated and controlled environment to test the amount of particles that leak, or pass through a poor fit and seal with the users face. The standard helps to increase the probability that respirators fit the majority of a particular worker population.

Ultimately, the ASTM Respirator Fit Capability Standard determines if a particular model of facepiece respirator will fit and seal to the users face and do the job it is intended to do. If you or your employees need to wear a respirator on the job to protect from dust, harmful chemicals, fumes, or gasses, it is essential to make sure that it works. And fit is a critical part of respirator performance.

The ASTM F3407 Standard provides detailed instructions for performing a respirator fit capability test on a panel of human subjects that is representative of the U.S. workforce in terms of face shapes. The standard calls for measuring the number of airborne particles that infiltrate and accumulate inside a respirator while wearers perform a set of common workday activities, such as bending, turning their head from side to side, heavy breathing and speaking.

Ultimately, the Respirator Fit Capability (RFC) Standard tests the capability of an N95 to fit a wide range of faces in the US workforce and whether or not the respirator is sealing to the users face.

"The ASTM RFC Standard will enable respirator manufacturers to develop better designed models that fit the worker population. Respirators passing the RFC Standard test method are expected to have better fitting characteristics."

NIOSH Science Blog

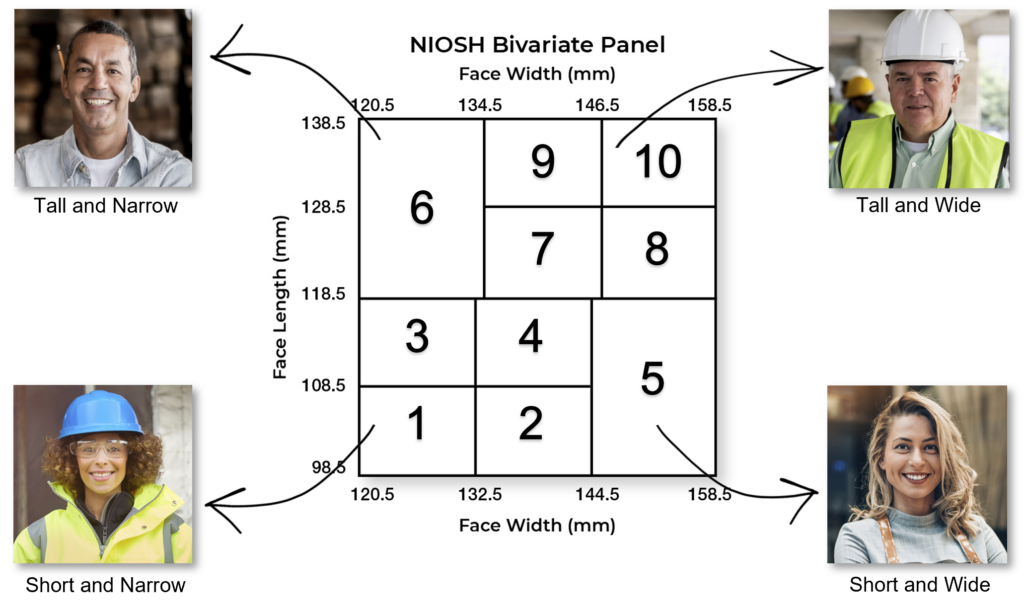

The RFC Standard tests are conducted in a calibrated laboratory environment with digital measurement equipment. The test procedures measure a respirator’s Fit Factor score on a minimum of 25 human subjects with various face sizes using the NIOSH Bivariate Panel representing the U.S. civilian workforce.

A passing score in the RFC Standard requires the test subject to score a minimum of 100 on a scale of 0 to 200+.

The Standard uses 25 test subjects with a variety of face shapes and sizes (see the NIOSH Bivariate Panel below) that represent the US worker population. Subjects are tested in a calibrated and controlled lab environment where equipment is used to measure the amount of particles that leak into the facepiece respirator. Remember, when you see leak, that means particles leak in through a poor fit or lack of seal between the respirator and the skin. The number of particles that leak into the facepiece respirator is divided into the number of particles outside the respirator in the controlled lab environment to generate each subjects results.

An RFC Standard result of 100 means that the number of particles outside the respirator is 100 times greater than inside. At least 13 of 25 (50%) test subjects must obtain an RFC result of 100 or greater for the respirator model to pass the RFC test.

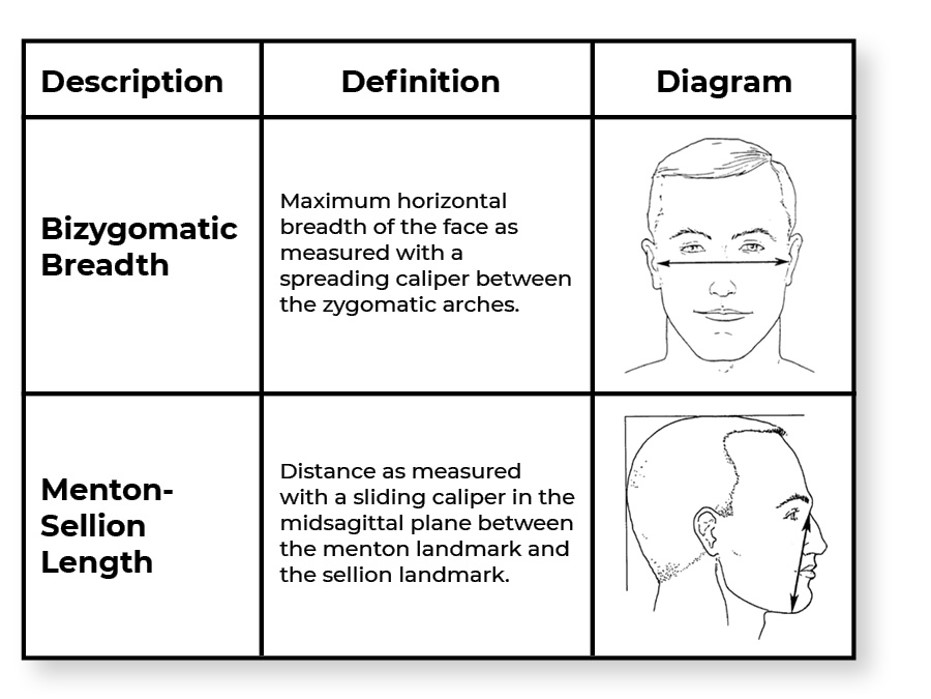

The NIOSH Bivariate Fit Test Panel has 10 individual cells with each cell representing a different face length and width. Cells 1, 2 and 3 are generally considered a small face size, cells 4, 5, 6, and 7 are considered a medium face size, and cells 8, 9, and 10 are considered the largest face sizes. A subject’s panel cell designation is determined by measuring their face length (menton-sellion length) and face width (bizygomatic breadth) with digital calipers.

American Society for Testing and Materials (ASTM)

ASTM International is a globally recognized leader in the development and delivery of voluntary consensus standards. Today, over 12,000 ASTM standards are used around the world to improve product quality, enhance health and safety, strengthen market access and trade, and build consumer confidence.

A respiratory fit test is used to verify that a selected make or model of N95 respirator properly fits, seals, and protects the employees or users required to wear the respirator for a specific task.

A fit test is not a general test, but a specific test administered for all brands and models of NIOSH-approved respirators to ensure that the wearer identifies the product that works best for them and their facial structure. Just like every individual’s facial structure is different, every make and model of an N95 respirator is shaped differently and therefore they do not fit all individual’s facial structures the same way.

The Occupational Safety and Health Administration (OSHA) outlines a protocol, as well as general requirements for fit testing, in Standard 1910.134 App. A. As part of the policy, employers must annually fit test employees who are required to wear a respirator to do their job.

Fit testing is not just an OSHA requirement for safer workplaces; it’s a matter of an employee’s livelihood. If you or your employees need to wear respiratory protection on the job to protect from dust, harmful chemicals, fumes, or gasses, you better make sure that it works. And the only way to do that is with a fit test.

Fit testing may seem like a nuisance to some, and because it can take time and expense to administer, companies may struggle to adhere to the annual OSHA requirements. But if your N95 respirator doesn’t fit properly, it will not protect you or do the job it is intended to do. If that’s the case, your level of protection may be no better than wearing no mask at all.

Employers and wearers have two options to conduct a fit test to determine the proper fit of an N95 respirator: quantitative fit testing and qualitative fit testing.

Fit Factor Score is the ratio of airborne particle count outside the respirator vs inside the respirator during a fit test procedure. NIOSH N95 approval calls for respirator samples to exceed a Fit Factor score of 100 or above.

Fit Capability Score is the percent of test panel subjects during ASTM RFC testing that achieved a Fit Factor Score above 100

A quantitative fit test uses a computerized precision instrument to measure the amount of leakage an N95 respirator may have when worn on a user’s face and then calculates the results. The result of the quantitative test is a Fit Factor score, which expresses how well that particular N95 fits the face of the test subject.

The measurement device, commonly known as a PortaCount® Respirator Fit Tester (by TSI Incorporated) determines how many airborne particles can break through the respirator’s seal while the wearer is simulating common body motions such as bending and head turns, as outlined in OSHA’s fit testing procedures.

Qualitative fit testing uses the body’s senses of taste and smell to detect a seal leak. Instead of using a machine to measure leakage, the tester drapes a loose testing hood over an individual wearing an N95. The hood is used to restrict ambient air from diffusing the airborne test solutions that are used to conduct the test. Qualitative fit testing can be conducted using strong sweet solutions, bitter solutions, or an irritant smoke.

The purpose of a respiratory program is to ensure that all employees required to wear respiratory protection as a condition of their employment are supplied with proper and well-fitting respirators and protected from respiratory hazards.

The operation and maintenance of a respiratory protection program is the responsibility of the employer.

Protex™ N95s are designed to fit the widest range of face shapes and sizes. And a better fit means better performance.

That’s Advanced Protection.

An N95 respirator that doesn’t fit and seal to your face properly may not protect you. Our Protex™ N95s are designed to fit.

An N95 respirator might feel comfortable to wear, but without proper fit-testing, the wearer has no way of knowing if it is leaking around the edges and not doing its job. We know; we’ve tested a lot of them, and there’s a lot of leakers out there!

Many employees have no way to fit test. But with the Protex™ N95, Shawmut took fit and protection surety to a new level. Our custom-designed cup and components have produced an N95 respirator with unparalleled fit capability based on the ASTM F3407 Respirator Fit Capability (RFC) standard.

Protex™ N95s meet the ASTM F3407-20 standard and are the only commercial N95s to claim this today. The Protex™ N95s achieve passing fit scores on close to 100% of subjects tested, far exceeding the ASTM standard.

The result is a single product line that can fit the vast majority of users and will simplify the fit testing for companies who have employee respiratory programs.

Please submit your questions and requests for information through the contact button and our respiratory team will review them in detail.