With the coming ascendancy of electric vehicles, there is an inflection point in the automotive industry where sustainability has moved from word to action. It’s no longer a suggestion or perk but a requirement.

As a result, sustainable optimizations related to electric motors, lightweight construction, and reduction of CO2 emissions are more critical than ever. And the role of the car’s interior can also be a key part of the equation. After all, the interior is the part of the car that the driver sees and experiences the most. Therefore, it is paramount that sustainable interior solutions be practical, aesthetically pleasing, and convey quality.

Sustainable Vision

At Shawmut, sustainability is always top of mind as we drive our product lines toward a cleaner and more renewable reality. Our engineers and scientists are constantly developing forward-looking composite materials that protect the environment, eliminate waste, and build a more sustainable now and future.

Years ago, when we began our sustainability journey for our automotive division, we set out to bring a family of sustainable fabrics to the table that met our ecological goals and made no compromises. At the time, sustainability and sustainable products, particularly in the automotive space, were fairly unconventional.

The Terra Story

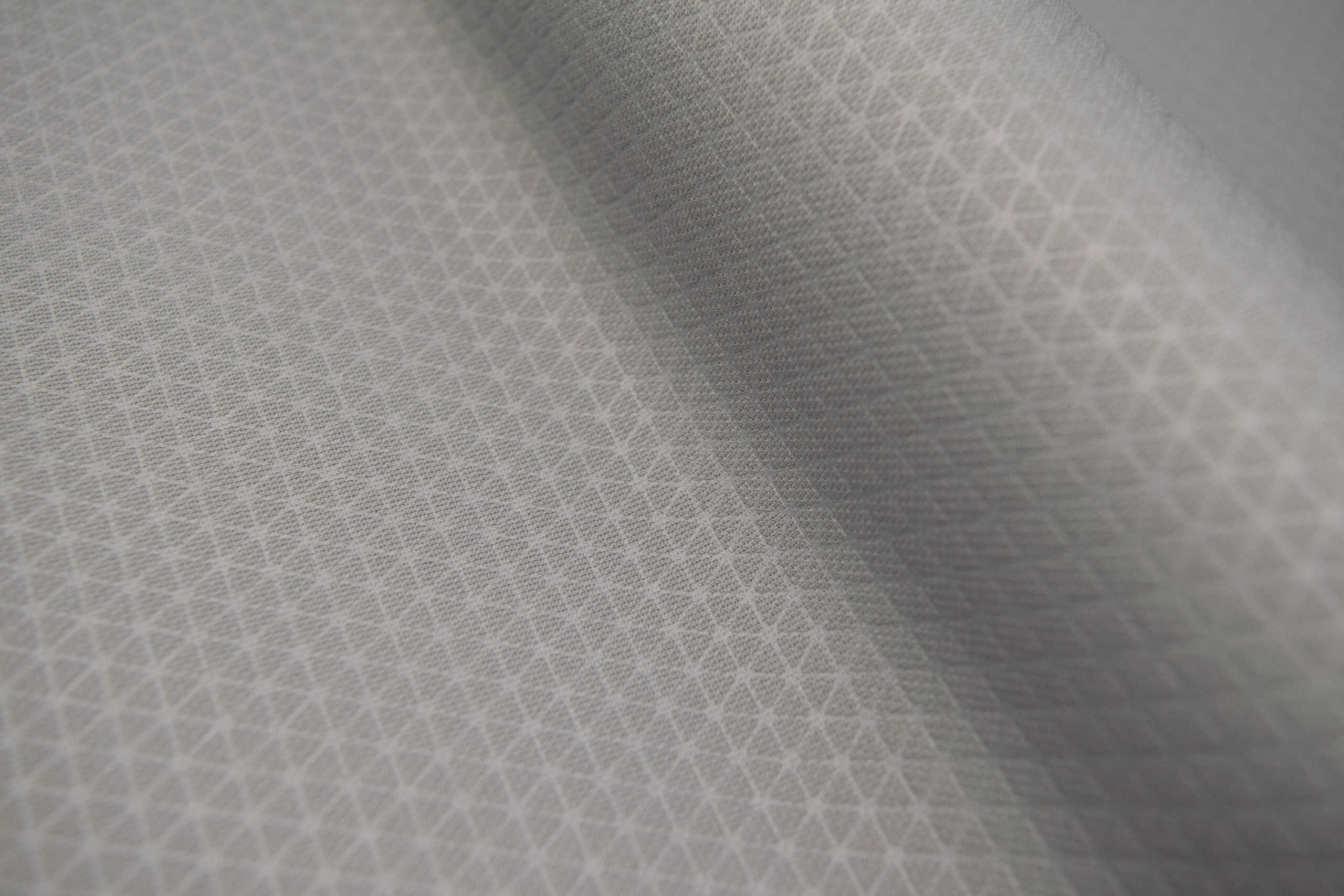

Originally sourced stateside from a crafty and hands-on team in North Carolina, we brought TerraTM (then Terrain) to market to add to our lineup of innovative and quality automotive interior fabrics. TerraTM fabrics are made of recycled water bottle yarn and are materials that we now use across all our automotive fabric interior capabilities. They meet recycled content standards by weight manufactured through a process of water bottles mixed with plant waste. And their hybrid nature and construction have the added benefit of making them more price-competitive. Along with Ford Motor Company, we were one of the first to adapt TerraTM-like recycled content fabrics and use them in the industry.

What makes the TerraTM family so appealing as automotive interior fabrics are they’re indistinguishable from other fabrics that are hallmarks of quality vehicle construction. They don’t fit a “sustainable aesthetic,” per se. Rather they blend right in, in the best way. The TerraTM fabric family doesn’t sacrifice anything in terms of performance, look, or feel to be sustainable, and that’s what our customers and we love about it. Sustainability works best when it doesn’t visibly stand out.

Sustainable Futures

Over the years, Nike and Patagonia (among others) have woven TerraTM-like yarns into their product lines, making TerraTM more attainable for our customers. Increased demand and better processes have dropped the prices to be in line with other fabrics in the category, which is impactful when automakers like General Motors and Volvo (amongst many others) are setting new sustainability targets daily. The drive for automotive sustainability and the pressure to find sustainable sources and sustainable automotive interior fabrics have gotten a little easier.

Sustainability (and sustainable automotive interior fabrics) can often come with compromises. With TerraTM, you can ensure you meet your ecological sustainability goals without sacrificing performance or quality. The price points are just a bonus. Solutions such as these are answers when the automotive industry is at an inflection point with sustainability and electric vehicles changing the paradigm daily.

What’s Next?

While TerraTM will remain a huge part of our sustainable mission going forward, we are also looking beyond the water bottle into wool blends and natural fibers as the next big things to weave into our lineup. Stay tuned for new environmental initiatives we’ll be announcing in the next few months.