As CMF (Color, Materials, and Finish) designers work to implement sustainability, they face the challenge of advancing innovation in an environment where cost pressures and limited regulatory drivers often slow progress. Materials once considered futuristic, such as high-content recycled textiles and mono material composites, are now shaping the next generation of vehicle interiors. These materials are not only redefining aesthetics but also addressing critical challenges related to recyclability, waste reduction, and scalability in automotive production.

Recycled content knit suede and mono material composites are at the forefront of this transformation, offering new possibilities in performance, design flexibility, and end-of-life recyclability.

Recycled Content Knit Suede: Sustainable Luxury at Scale

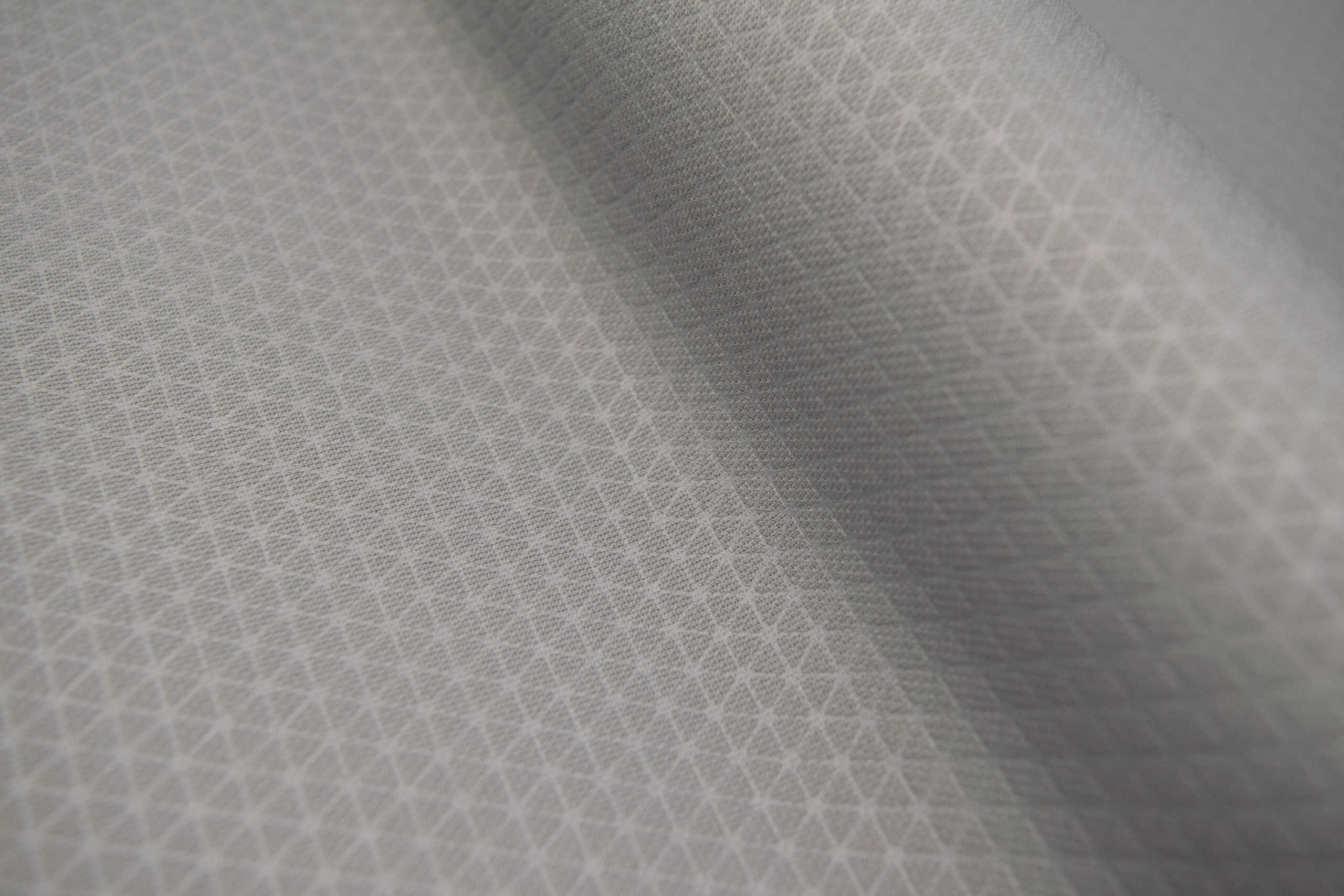

The demand for premium, sustainable materials in automotive interiors has led to the development of high-performance recycled content textiles. One of the most promising innovations in this space is recycled content knit suede, which embodies both luxury and environmental responsibility.

What is Recycled Content Knit Suede?

Recycled content knit suede is a soft, durable material created by transforming post-consumer or post-industrial waste into high-quality fibers. With varying levels of recycled content, this textile offers automakers an opportunity to reduce waste and conserve resources without compromising on aesthetics or performance.

Why is This Material a Game-Changer?

- Sustainable Sourcing: Instead of relying on virgin materials, recycled content knit suede upcycles existing waste, contributing to a circular economy.

- Versatility and Aesthetic Appeal: This material can be laser-etched, printed, or textured, providing CMF designers with a wide range of creative possibilities for premium interiors.

- Superior Molding Capabilities: Unlike some sustainable alternatives that lack flexibility, recycled knit suede molds beautifully, making it ideal for complex automotive interior applications.

- Scalability: The ability to produce this material at high volumes makes it a viable option for mass production, one of the biggest hurdles for sustainable materials.

CMF professionals embracing recycled suede are proving that sustainability and luxury are not mutually exclusive, as they can coexist in a way that enhances both the vehicle interior and the planet.

Mono Material Composites: Simplifying Design for a Sustainable Future

Another groundbreaking shift in automotive textiles is the rise of mono material composites, which are textiles and structures designed with compatible single-polymer systems that enable easier recycling and material recovery.

What Are Mono Material Composites?

Unlike traditional automotive materials that combine multiple layers of different fibers, foams, and adhesives, mono material composites are engineered using a single family of compatible materials. This approach reduces the complexity of disassembly and improves recyclability at the end of a vehicle’s life cycle.

Key Benefits of Mono Material Composites

- Enhanced Recyclability: Since all components within a composite share similar polymer chemistry, they can be more easily reclaimed and reprocessed, supporting true circular design.

- Reduced Material Waste: By eliminating unnecessary layers and adhesives, mono material composites streamline production and reduce both material use and energy consumption.

- Functional and Aesthetic Innovation: New developments in mono material composites allow for advanced surface effects, texture control, and thermal formability. Designers can achieve refined, seamless surfaces that replace heavier or multi-material structures, enabling lightweight, elegant, and sustainable interiors.

Challenges to Mono Material Composite Adoption

Despite their advantages, integrating mono material composites into production vehicles presents several challenges:

- Engineering Integration: These materials must meet stringent automotive standards for durability, comfort, and appearance while replacing long-established multi-layer systems.

- Market Readiness: CMF professionals must educate both designers and manufacturers on the advantages of mono material composites and their viability in mass production.

- Cost vs. Sustainability Debate: While these composites offer long-term sustainability benefits, initial development and process retooling can increase upfront costs.

Despite these hurdles, mono material composites represent a fundamental shift in the way vehicle interiors are designed, moving toward minimalism, recyclability, and smarter material systems.

The Challenges of Integrating Sustainable Materials in Automotive Design

While materials like recycled knit suede and mono material composites present exciting opportunities, CMF professionals face significant barriers when introducing these innovations into production vehicles. The three biggest hurdles include:

- Scalability

Many cutting-edge materials, especially those sourced from bio-based origins or recycled inputs, struggle with scalability. A material that works in prototype production might fail in mass production due to inconsistencies in supply, performance, or processing capabilities. For a material to make it into an OEM program, it must be available at scale, without quality fluctuations. - Cost and OEM Adoption

OEMs operate under strict cost constraints, and while sustainability is an increasing priority, materials must remain economically feasible. Sustainable textiles often involve higher initial development costs, making it crucial for CMF teams to demonstrate long-term value, whether through recyclability benefits, regulatory compliance, or premium branding opportunities. - Performance and Durability

When selecting sustainable materials for automotive applications, performance and durability are critical. Materials must meet strict testing standards to ensure they can withstand the demands of real-world use. Failure to pass these tests can compromise their suitability for production vehicles. CMF professionals play a key role in balancing sustainability objectives with long-term durability, making sure that every material performs reliably throughout the life of the vehicle. Key considerations include:

- Abrasion resistance

- UV and temperature stability

- Flammability compliance

The Path Forward: A Future Built on Sustainable Innovation

The adoption of recycled and mono material composites in automotive interiors signals a shift toward responsible, circular design. As CMF professionals, the challenge is not just to identify sustainable materials but to navigate the complexities of production, performance, and OEM acceptance.

Moving forward, success in sustainable automotive interiors will require:

- Stronger collaboration between material suppliers, OEMs, and design teams

- Advancements in textile and composite engineering to improve durability and performance

- Consumer education to drive demand for eco-conscious interior materials

By pushing the boundaries of recyclability, material efficiency, and smart composites, CMF designers have the power to reshape the future of automotive interiors, creating vehicles that are both beautiful and sustainable.