Water scarcity is a critical global issue that demands innovative solutions. As the demand for clean and safe water continues to rise, advancements in water purification technologies play a pivotal role in addressing the challenges associated with global water shortages. Among these technologies, reverse osmosis (RO) has emerged as a powerful method for purifying water. This blog explores the transformative impact of textile technology on water filtration, with a specific focus on the rise of reverse osmosis and the critical role played by permeate carrier fabrics, such as Shawmut’s industry-leading RO-Flow®.

The Rise of Reverse Osmosis

Reverse osmosis (RO) has become one of the most widely adopted methods for water purification, known for its efficiency and effectiveness in producing high-quality potable water. But what exactly is reverse osmosis, and why has it gained such prominence?

Reverse osmosis is a water treatment process that removes contaminants from water by using pressure to force water molecules through a semi-permeable membrane. This membrane allows only water molecules to pass through while rejecting larger molecules and ions such as salts, bacteria, and other impurities.

How Reverse Osmosis Works

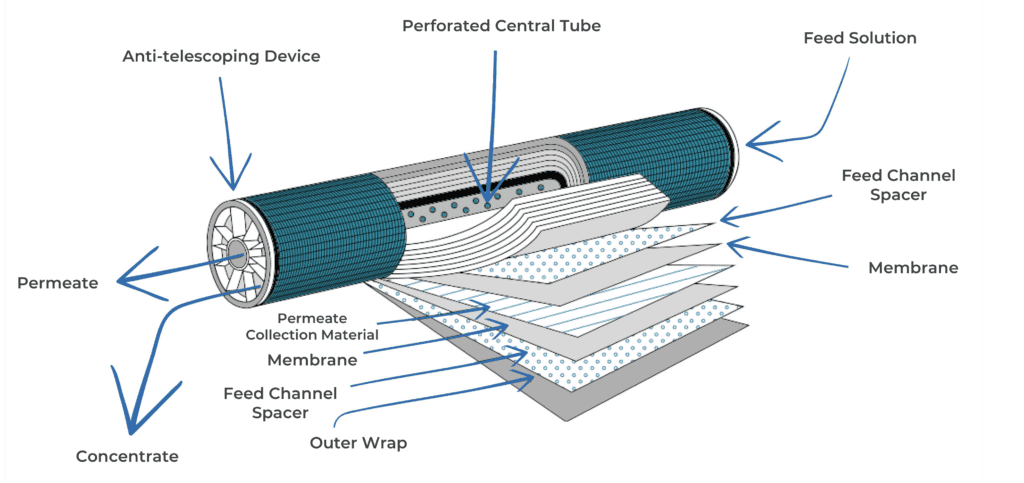

The process of reverse osmosis involves several stages:

- Pre-filtration: This initial stage involves removing larger particles and sediments from the water to protect the RO membrane from damage and fouling.

- Pressurization: Water is then pressurized using a pump to overcome the natural osmotic pressure. This pressure is crucial as it pushes water molecules through the semi-permeable membrane.

- Membrane Filtration: At the heart of the process, the semi-permeable membrane separates pure water from contaminants. The membrane’s pores are incredibly small, typically around 0.0001 microns, allowing only water molecules to pass through while blocking contaminants.

- Post-treatment: The purified water, known as permeate, is collected, and any residual tastes or odors are removed through additional post-treatment filters if necessary.

In industrial RO systems, the semi-permeable membrane is contained inside a large cylindrical tube in which untreated water enters at one end of the tube and exits at the other. Inside the tube, water molecules are forced through several layers, or wraps, of membrane. The membrane wraps are held apart from one another by an adjacent layer of permeate carrier fabric, which contains specially created parallel channels to allow for the exit of water after the molecules have pass through the membrane layers. If the permeate carrier fabric is not strong enough to maintain its separation of the membranes through the pressure required to force the permeate through the membrane, the system collapses and water flow is restricted.

Advantages of Reverse Osmosis

Reverse osmosis offers several significant advantages that have contributed to its widespread adoption:

- High Efficiency in Contaminant Removal: Reverse osmosis can effectively remove up to 99% of dissolved salts (ions), particles, colloids, organics, bacteria, and pyrogens from water. This high level of contaminant removal makes it suitable for a wide range of applications, from household water purification to large-scale industrial processes.

- Versatility: RO systems can be used to treat water from various sources, including municipal supplies, wells, and even seawater, making them highly versatile in different settings and industries.

- Improved Taste and Safety: By removing impurities, reverse osmosis significantly improves the taste, odor, and appearance of water. It also reduces the risk of waterborne diseases, making it a safe choice for drinking water.

- Environmental Benefits: Unlike traditional water treatment methods that often require the use of chemicals, reverse osmosis is a physical process that relies on pressure, thus reducing the need for harmful chemicals in water treatment.

The Critical Role of Permeate Carrier Fabrics

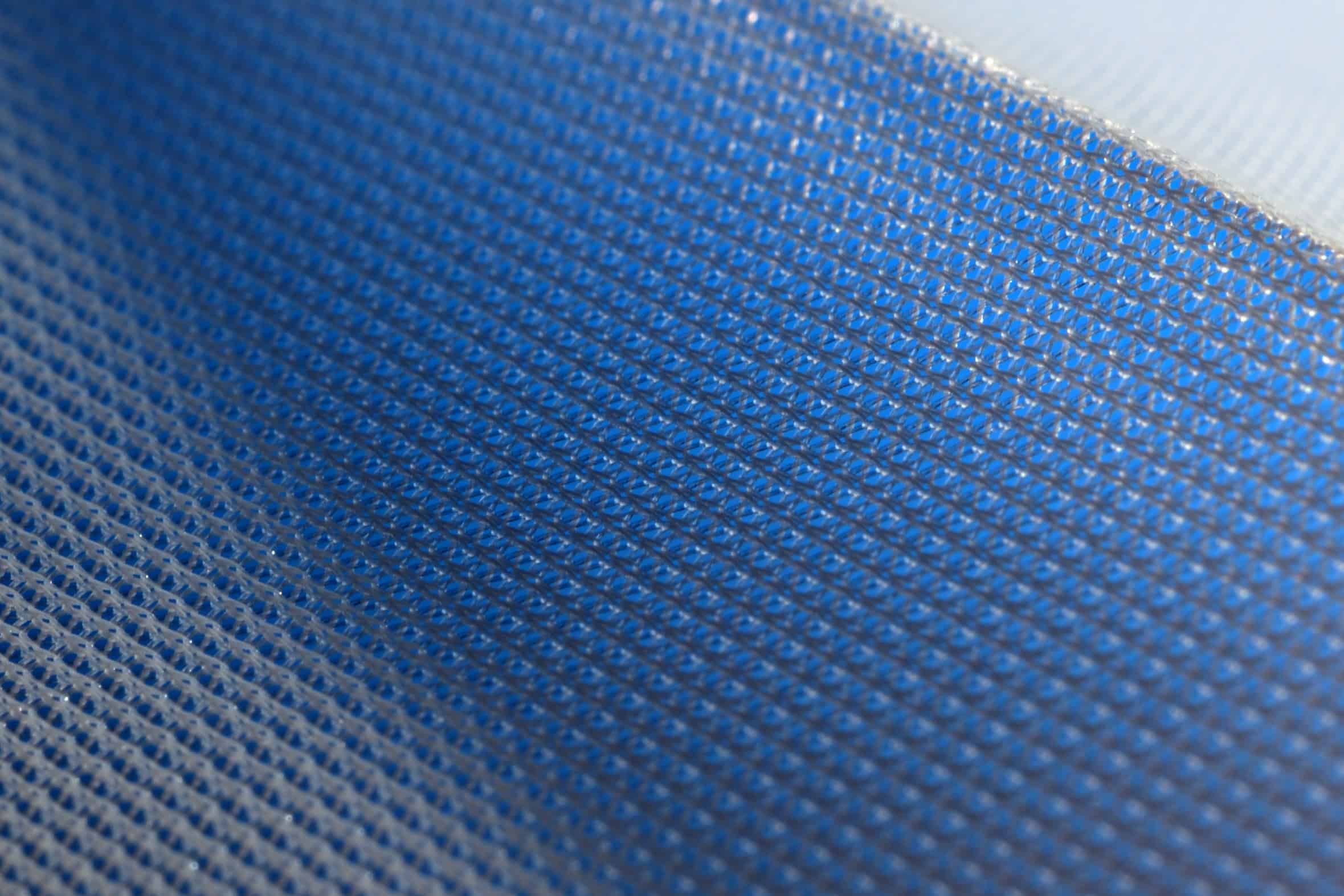

While the membrane is the core component of the RO system, the efficiency and durability of the system are significantly enhanced by permeate carrier fabrics such as Shawmut’s RO-Flow®. These fabrics support the membrane and facilitate the efficient flow of purified water.

Shawmut’s RO-Flow permeate carrier fabrics have become synonymous with high-performance water filtration. Let’s delve into the key features that make RO-Flow a game-changer in the reverse osmosis process:

- Maximum Channel Integrity: RO-Flow® is designed to provide exceptional strength and durability through maximum channel integrity. This ensures the longevity and reliability of the permeate carrier in facilitating the filtration process under high-pressure systems.

- Thinner Construction for Increased Wraps: The thinner construction of RO-Flow® allows for a greater number of wraps of membrane around the tube core. This innovation enhances the efficiency of the reverse osmosis system by optimizing the contact between the permeate carrier and the membrane.

- Wider Channels for Enhanced Flow Rate: The wider channels on RO-Flow® permeate carriers contribute to a higher fluid volume output and an increased flow rate compared to competitive products. This leads to a more efficient water purification process.

- Hybrid Tricot Design for Membrane Customization: The hybrid tricot design of RO-Flow® offers flexibility, supporting membrane customization. This adaptability ensures compatibility with various reverse osmosis configurations, contributing to the versatility of the water purification system.

- Exceptional Firmness and Compression Resistance: RO-Flow’s exceptional firmness minimizes compression, setting it apart from traditional multifilament yarns. This feature reduces the risk of flow loss over time, maintaining the efficiency of the reverse osmosis process.

- Eco-Friendly, Safer Alternative: Shawmut’s commitment to environmental sustainability is evident in RO-Flow’s eco-friendly design. The incorporation of heat-treated bicomponent yarn eliminates the need for harsh chemicals or epoxy in the construction of the fabric, making it a safer alternative for water filtration.

Solving Global Water Shortages

As the world grapples with water scarcity, the importance of advanced water filtration technologies cannot be overstated. Reverse osmosis, powered by cutting-edge permeate carrier fabrics like RO-Flow®, provides a sustainable and effective solution to address the challenges associated with water shortages. The efficiency, durability, and eco-friendly features of RO-Flow contribute to its role as an industry leader in the quest for clean and accessible water.

Conclusion

The integration of textile technology into water purification processes marks a significant step forward in addressing global water shortages. The rise of reverse osmosis, coupled with the outstanding performance of permeate carrier fabrics, exemplifies the potential of innovation to create sustainable solutions. As we continue to advance in the field of water filtration, it is crucial to prioritize technologies that not only meet performance standards but also align with environmental sustainability goals. RO-Flow® permeate carrier fabric stands as a testament to the possibilities of textile technology in revolutionizing water purification and, in turn, contributing to a more water-secure future for our planet.