InfinKnit™

Versatile

Spacer Knit

Innovation Meets Sustainability

Luxurious, Eco-Friendly Automotive Interior Solutions Redefined

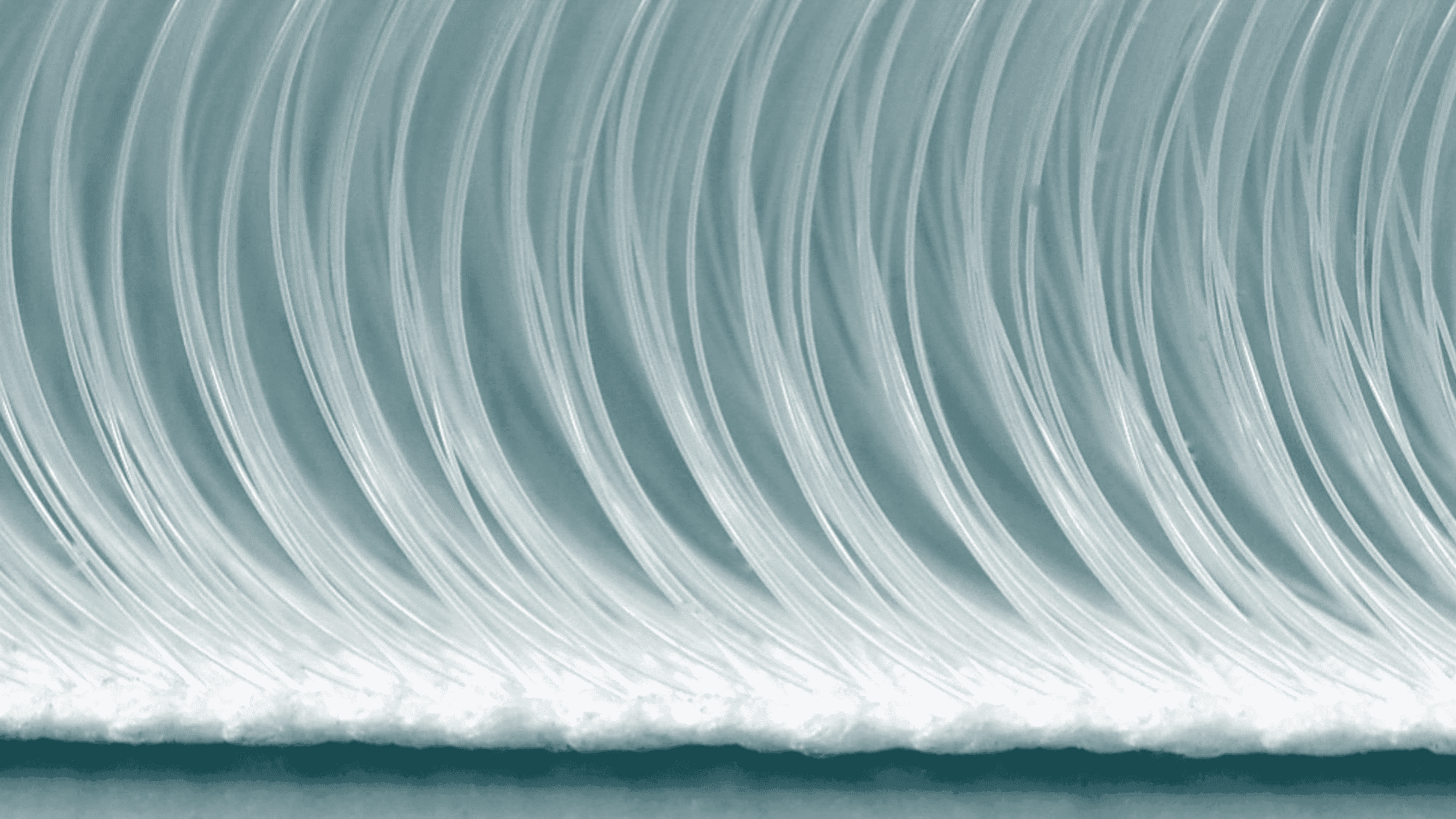

InfinKnit™ Spacer Knit represents a groundbreaking advancement in automotive interior materials, offering an alternative to traditional face fabrics and foam-based composite solutions. Its innovative dimensional knit structure, featuring a plush inner layer seamlessly integrated into the face and back material, ensures both durability and enhanced climate control.

Lightweight, recyclable

mono-material

Enhanced comfort and

sustainability

Composite alternative for

auto interiors

Superior durability and

climate control

Pioneering Sustainability

with InfinKnit™ Spacer Knit

At the forefront of automotive material advancements, InfinKnit™ Spacer Knit redefines sustainability with its innovative design and eco-friendly attributes, meeting the highest standards of modern, sustainable materials.

Key Sustainability Features:

- Mono-Material Design: As a lightweight, mono-material fabric, InfinKnit simplifies recycling processes and reduces material complexity, further enhancing its environmental benefits.

- Minimal Emissions: InfinKnit Spacer Knit is crafted with a focus on reducing emissions throughout the production process. This minimizes its environmental impact from start to finish.

- Extended Lifespan: Designed for durability, InfinKnit boasts a long service life, ensuring that its environmental benefits are sustained over time, reducing the need for frequent replacements.

- 100% Recyclability: True to our commitment to a circular economy, InfinKnit Spacer Knit is fully recyclable, allowing it to be reintegrated into the material cycle at the end of its lifecycle.

From Production to Recycling – A Sustainable Journey

InfinKnit Spacer Knit represents more than just a material choice; it’s a step towards a greener future. By opting for InfinKnit, you contribute to a significant reduction in environmental footprint, embracing a fabric that is as responsible as it is innovative.

A Revolutionary Alternative to Composite Layers

For decades, designers and materials engineers have sought a viable alternative to composite layering within vehicle manufacturing, aiming to reduce dependency on traditional foam materials. InfinKnit™ Versatile Spacer Knit emerges as the definitive solution to this longstanding challenge. With its innovative design and composition, it revolutionizes automotive interiors by offering an alternative.

Discover the Innovation of InfinKnit™

Unmatched Versatility

Superior Comfort

Seamless Integration

Enhanced Illumination

InfinKnit™ Spacer Knit revolutionizes automotive interiors by replacing plastic housing components in headliners with its light-transmissible fabric. Experience its impact through enhanced illumination, optimal light diffusion, sustainable material composition, and seamless integration into existing designs.

Versatile Applications and Customization

Explore the limitless possibilities with InfinKnit™ Versatile Spacer Knit, offering unparalleled customization options including light-transmissible fabrics, adaptable designs, and seamless integration. Reimagine automotive interiors with InfinKnit and set new standards in comfort, sustainability, and innovation.

Explore InfinKnit™

The Shawmut Difference

Exacting Production

Our vertical integration from fabric design through warping, knitting, dyeing, coating, chemical finishing, and mechanical finishing ensures that your final assembly process will go as smoothly as possible.

Color Control Expertise

Process control and lot testing digital inspection technology with machine learning closely monitors color consistency to ensure that the color you approve is consistent throughout the life of your program.

Dynamic Materials and Interior Solutions

As a leading provider of advanced engineered materials for automotive interiors, we offer a wide range of solutions, including sun visors, headliner fabrics, door and console trims, overhead sunshades, and seating fabrics.

Global Technology Network

A global production platform guarantees the replication of production processes across multiple continents, showcasing our dedication to consistency and ensuring that our advanced engineering technology is accessible worldwide.