A few months back, COVID-19 pandemic cases were waning in the US as vaccination rates took hold and we spent more time outdoors. However, new coronavirus variants emerged, and the vaccine rollout remained sluggish in many areas of the country, causing cases to rise again. It is still clear that masks continue to play a critical role in mitigating the spread of the virus and experts and government officials have been recommending more widespread masking practice to protect against the highly contagious Delta variant.

Studies have shown that masks significantly decrease transmission chances, but not all masks provide equal protection. N95 masks are ideal in personal protective equipment (PPE) because they block 95% of large and small particles utilizing a unique electrostatic filter. European countries such as Germany and France had already taken that step earlier this year, mandating all citizens wear high filtration masks like the N95 in all public spaces. Furthermore, in the US, some strongly believe that if worn for four weeks in risky scenarios, the N95 would stop the epidemic. So, why aren’t more in use in the US?

The short answer is the supply chain. While the Biden administration has, short of legislation, committed to supporting and boosting the domestic manufacturing of N95s, many distributors and sellers are still trying to source from overseas even though ample sources are available domestically. Increasing the output of N95 masks made in the USA could also improve the general public’s protection as most Americans are still wearing cloth masks, which are not as effective. And like the early days of the pandemic demonstrated, sourcing these critical supplies from foreign countries (and suppliers) at a time of crisis is not a timely, effective, or capable solution.

A year ago, it was difficult, if not impossible, to source PPE from foreign countries as it was embargoed locally. Today, as sourcing of goods from overseas is rife with long delays, much higher shipping costs, and continued container shortages and port congestion, many sellers of PPE are reconsidering the sources they employ and are looking more to domestic manufacturing of not only the finished product, but the raw materials as well.

American-made manufacturing can respond and scale to answer national PPE needs in a manner difficult for foreign bodies to match. US-based N95s can ship to market faster and provide the same, or often better, quality at a competitive price. Moreover, full control of the manufacturing process will ensure lasting quality, safety, and reduce dangerous counterfeits and opportunistic price gouging. Domestic production will also allow first responders and medical personnel to partner with the local factory to permit rapid prototyping and testing of future PPE products.

Shawmut and our development partner, The Fallon Company, have recognized this emergent need and developed, in record time, an innovative world-class US process and N95 product to supply a nation and people in crisis. We have committed nearly $20 million to build a state-of-the-art N95 production plant with the capacity to produce 180 million masks per year. We’re bringing real PPE solutions to the table using agile development techniques and took the plant from concept to production in less than five months.

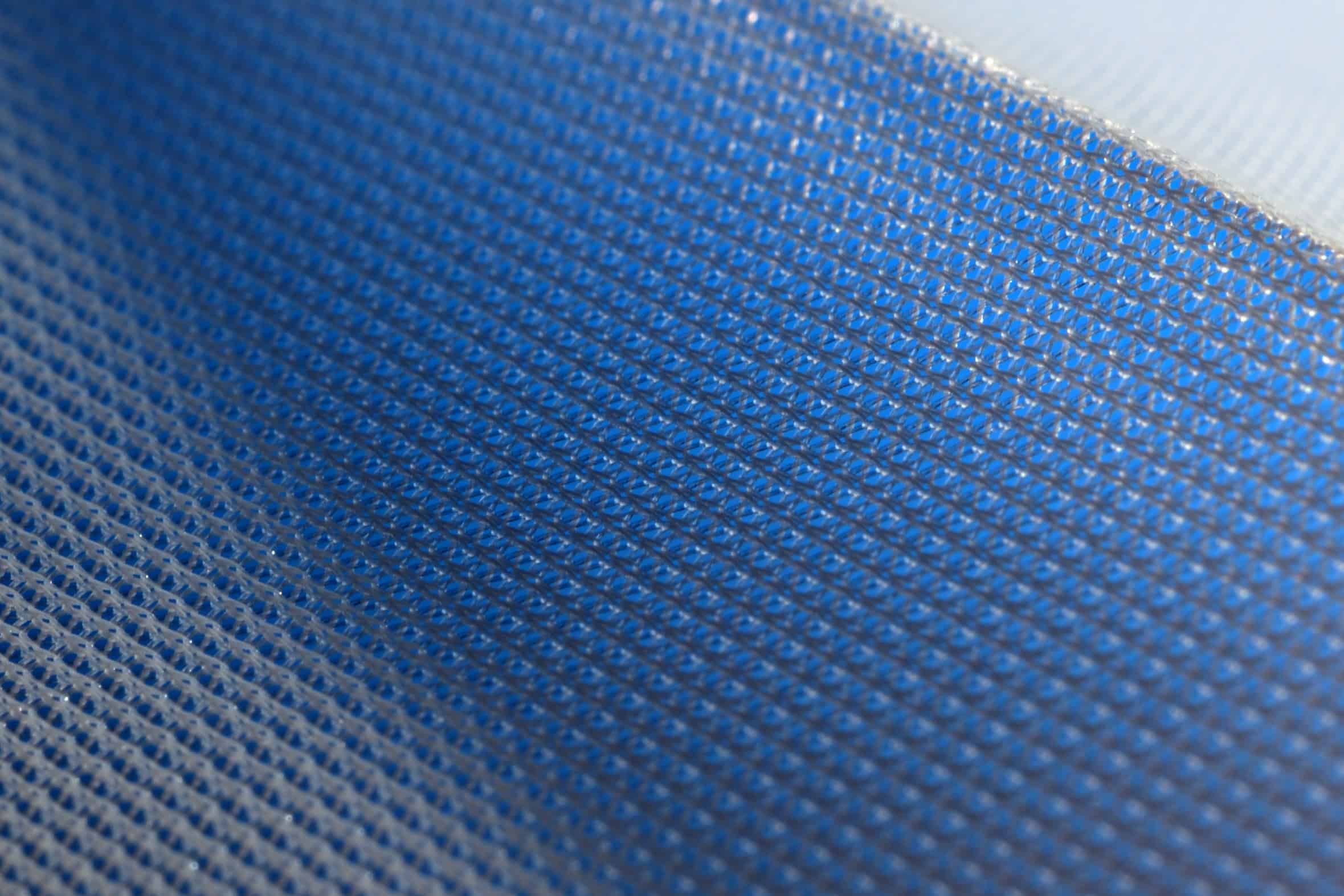

We installed the world’s most advanced melt blown filter media production system from Reifenhauser (a world-class equipment manufacturer), and a fully automated and flexible molded cup-mask production system. Molded cups are the gold standard in N95 masks but also the most challenging to manufacture. This level of skillful engineering and quality materials is crucial in a market rife with fakes and less effective KN95s. It also provides a unique combination of a secure fit and all-day comfort that will help broaden the everyday use of N95 masks. Our new buildout for cutting-edge N95 manufacturing has been online since February.

We are committed to helping ensure our country will never run out of N95 masks again. And we are at the ready, looking to be part of the solution to this ever-pressing pandemic. Check out our Protex N95 masks made in the USA here.

Editor’s note: This blog was originally published on February 1, 2021 and has been updated in August 2021 to reflect the current impact of the pandemic.