West Bridgewater, MA – Jul 21, 2021 ─ Today, Shawmut Corporation unveiled new renovations at its Park Avenue Technical Center, one of the largest and most technologically advanced fabric finishing operations in the US, located in Burlington, North Carolina. The updates offer Shawmut customers easier access to the company’s advanced materials design and collaboration facilities and provide increased speed, agility, and flexibility for custom solutions development. Customers visiting the facility will have access to Shawmut’s world-class design, engineering, technical, and program management staff, all under one roof.

The Park Avenue Technical Center renovations augment Shawmut’s existing 180,000 square foot facility with a new multi-story program and technical development center with state-of-the-art customer meeting and collaboration capabilities. The overall facility, which includes office, lab, manufacturing, and warehouse space for the location’s 145 employees, features:

- A newly constructed office and customer experience wing

- A rapid color formulation center

- Technical, quality, and color labs

- Investments in on-site customer collaboration and accelerated product development processes

“The southeast is a hub for the US textile industry, and the updates we have made to our Park Avenue Technical Center, in the heart of this region, will allow us to further our commitment to helping customers solve pressing business challenges rapidly through advanced materials innovation,” said James Wyner, CEO of Shawmut Corporation. “Innovation is at the heart of everything we do at Shawmut and providing our employees with new customer experience spaces will only foster greater thinking and ingenuity for our world-class team of engineers, designers, and marketers to continue creating better materials solutions for our customers.”

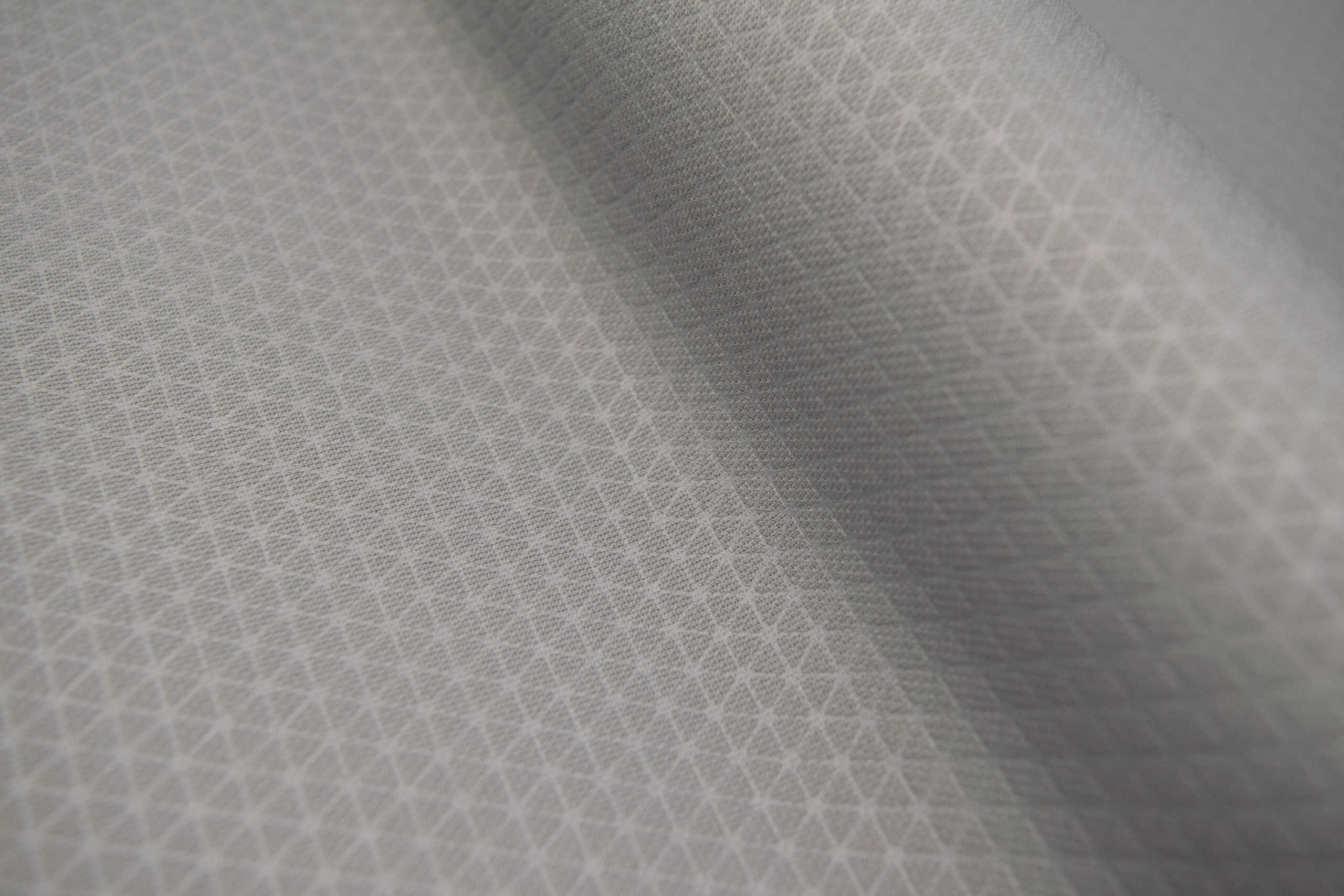

The Technical Center supports several of Shawmut’s core markets, including Military & Protective, Health & Safety, and Custom Solutions; however, the main output at the facility is Automotive-related advanced materials. Shawmut is the majority supplier of laminated automotive headliner materials in North America. More than 50% of all cars produced today for the North American market have headliner materials from this facility. In addition to headliners, the company also makes laminated materials for automotive pillars, sun visors, sunshades and panoramic roof roller shades, seating, door and trim laminations, package trays, and parcel shelves.

A More Sustainable Manufacturing Facility

As the world becomes more invested in sustainability efforts, so too does Shawmut’s commitment to a more sustainable future through material innovation and environmental management. Shawmut’s Park Avenue Technical Center is the company’s first ISO 14001 certified facility. It is 100% landfill-free, with less than 1% of the waste from the Technical Center going to a landfill, and instead repurposed through recycling and other external sustainability operations. Locally, the facility is recognized in the top 1% of businesses for safety and culture activities by the state of North Carolina and is a member of the Carolina Star program that recognizes worksites that are self-sufficient in their ability to control hazards at the worksite. Additionally, Shawmut has made strides in its water conservation efforts at the Park Avenue Technical Center, cutting water usage by nearly 75% over the last several years.

Sustainability Efforts by the Numbers:

- 704,627 gallons of fossil fuels saved by recycling instead of producing virgin products

- 1,076 trees saved by recycling all paper and pulp products

- 2,629,416 metric tons of CO2 saved by recycling instead of landfilling

- 3,650,257 kWh of energy saved by recycling instead of producing virgin products

“At Shawmut, we pride ourselves in our ability to quickly adapt to changes in the industries we serve to ensure we are meeting the dynamic needs of our customers,” said Eddie Gant, Jr., Senior Operations Director at Shawmut and manager of the Park Avenue Technical Center. “Our customers are prioritizing improving their sustainability, and we want to support their goals with products that can play a role in a more sustainable future. We are committed to doing our part to reduce CO2 emissions, developing new processes and protocols to consume less energy and water and produce less waste for our company and our customers.”

###

About Shawmut:

Shawmut Corporation uses materials innovation to improve people’s lives, employing expertise in fabric formation, coating, and laminating to deliver high-performance materials and components to the Automotive, Health & Safety, Defense, Protective, and Custom Laminating Solutions verticals. Shawmut’s world-class team of applications and materials engineers works with customers to define detailed performance requirements. It leverages deep expertise and decades of application experience to design a value-driven material solution for the need. As a fourth-generation, family-run global company headquartered in West Bridgewater, MA, Shawmut employs over 700 employees worldwide in ten manufacturing plants and seven commercial offices across North America, Europe, and Asia. Shawmut can be found online on LinkedIn, Facebook, and Instagram. To learn more, visit www.shawmutcorporation.com.