Engineering a Cleaner,

Smarter Future

From advanced materials to advanced manufacturing, Shawmut

is building sustainability into every layer of what we make.

Our Commitment to

a Sustainable Future

At Shawmut, sustainability isn’t a trend, it’s an expectation.

With more than a century of material innovation, we understand that true progress means improving how we create, not just what we create.

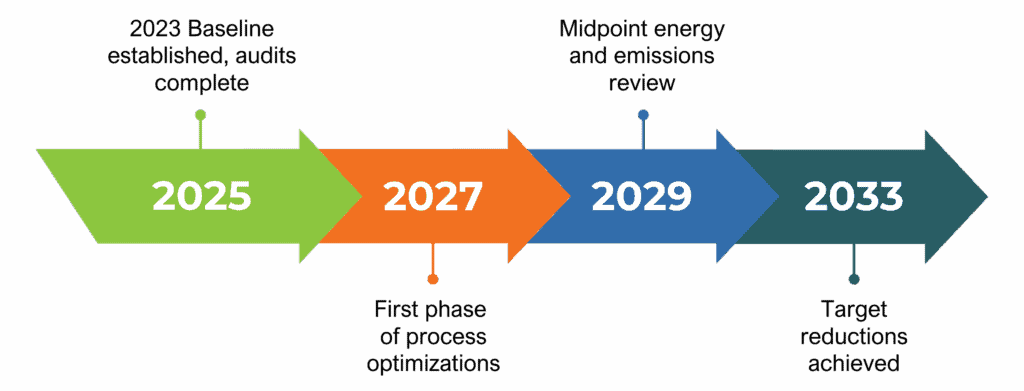

That’s why we’ve joined the U.S. Department of Energy’s Better Buildings, Better Plants Program, committing to:

- 25% improvement in energy intensity within 10 years from a baseline of 2023

Five of our North American manufacturing sites are enrolled in this initiative, representing the majority of Shawmut’s operational footprint in the United States. Through this partnership, we’re applying the same data-driven rigor that defines our engineering to how we measure and reduce our impact.

Reducing Our Operational Footprint

Every watt, every BTU, every gallon of water matters. Across Shawmut’s 16 global facilities, our engineering and operations teams are implementing projects that directly reduce energy use and emissions.

Our efforts begin with the most energy-intensive parts of our process—textile dyeing and finishing—where we’re investing in:

- Thermal energy optimization through advanced heat recovery systems

- High-efficiency dyeing and finishing equipment

- LED lighting, compressed air, and process airflow upgrades

- Renewable energy sourcing and energy audits for continuous improvement

Our approach is iterative and measurable. Every improvement is logged, analyzed, and benchmarked to track progress toward our 2033 goals.

"We’ve built our reputation on performance. Now we’re building our future on sustainability.”

James Wyner, CEO, Shawmut Corporation

Measuring Impact with Shawmut Insights™ LCA

Real sustainability demands real data. That’s why Shawmut created the Shawmut Insights™ Life Cycle Assessment (LCA) system, a proprietary platform built to ISO 14040 and 14044 standards that evaluates the cradle-to-grave environmental impact of our products. By integrating primary data from our facilities and supplier network with our custom LCA model, Shawmut Insights™ provides a detailed, verified understanding of where emissions and energy use occur, and where they can be reduced. This capability allows us and our customers to:

- Quantify the carbon footprint of any fabric or composite we produce

- Evaluate materials and methods to identify lower-impact alternatives

- Support OEM sustainability targets and procurement criteria

The result is a more transparent, accountable, and collaborative path toward lower-carbon materials.

See How Shawmut Insights™ Works

Sustainable Product Innovations

Sustainability is engineered into our materials from the start. Our development teams combine deep textile science with circular design thinking to create materials that perform better with less environmental impact.

Each of these innovations demonstrates how Shawmut combines measurable sustainability with advanced engineering and design, creating materials that perform better, last longer, and reduce environmental impact.

Partnering for Progress

Progress is a shared effort.

Shawmut collaborates with public, private, and industry partners to accelerate sustainability innovation across our value chain.

Our partnerships include:

- The U.S. Department of Energy’s Better Buildings, Better Plants Program

- Independent sustainability consultancies for LCA verification

- OEM Automakers and Tier 1 partners developing low-carbon supply chains

- Certification and benchmarking through ISO, bluesign®, and EcoVadis frameworks

By working with our customers and suppliers, we ensure that every advancement we make can be multiplied across industries.

Looking Ahead

As we progress toward our 2033 goals, Shawmut is expanding renewable energy evaluations, broadening the scope of our LCA database, and exploring new materials built for circularity and recyclability.

We’ll continue to share updates through the DOE’s Better Buildings network and our own sustainability reports—demonstrating progress that’s transparent, verifiable, and meaningful.