We apply our expertise in textiles, fibers, foams, films, coating, laminating, and surface treatments to develop custom engineered, high-performance flexible materials to help solve hard problems.

Shawmut makes materials that perform in some of the toughest applications in some of the world’s most demanding industries. Our applications experience across industries has taught us how to understand the performance challenges and design a material that will excel in the application.

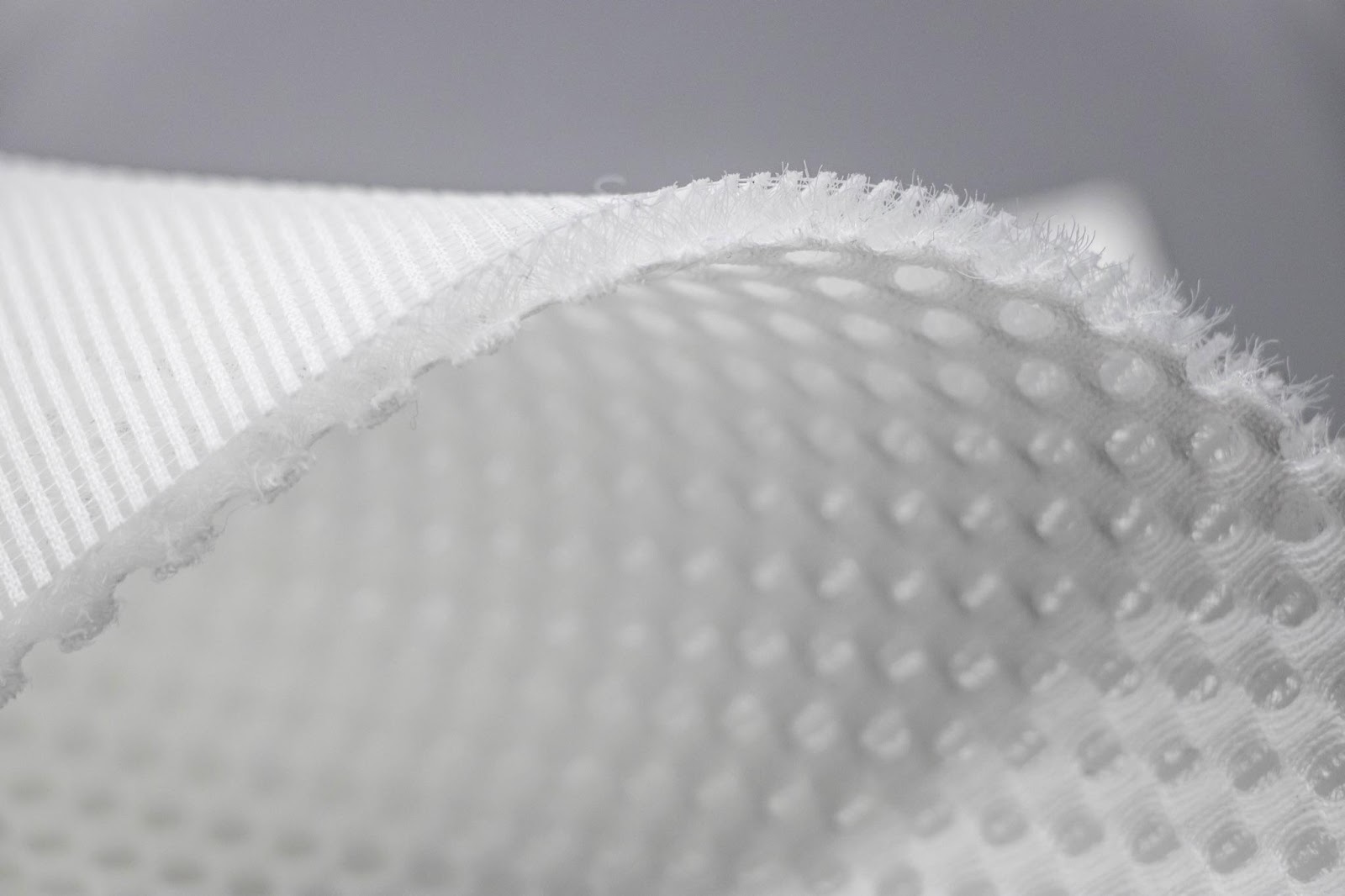

From moldability, durability and controlled porosity, to viral barriers, flame protection, extreme wash durability and recyclability, Shawmut has years of experience in laminating flexible materials.

Shawmut Corporation is one of the leading technical fabric lamination providers in the U.S. and globally. Our advanced textile lamination technologies help us to produce high-quality, durable fabric laminates that meet the specific needs of our clients.

Explore these advanced process technologies that shape our multi-composite products.

Shawmut produces laminates by bonding foam/fabric or foam/film by passing the foam over an open flame using our advanced burner technology. Exposure to the flame creates a thin layer of molten polymer on the foam surface that is brought into contact with the second layer under pressure to develop a bond between the two surfaces. Our proprietary tension and winding systems allow for lower material consumption and faster throughput.

Performance Specifications:

We implement thermoplastic or reactive adhesives through direct printing of moving webs via anilox gravure roll, which is then combined under controlled conditions. Shawmut maintains a portfolio of applicator rolls with various discontinuous patterns to achieve a diverse range of adhesive laydowns and coverages that influence physical properties and performance. This textile lamination technology platform can process advanced materials utilizing a roll coating methodology, enabling the application of a continuous coating of adhesive or polymeric compounds.

Performance Specifications:

Thermoplastic materials available in a wide range of available formats are applied on thermal lamination equipment, including oil heated drums with Teflon coated conveyor belts and Flatbed systems utilized to create adhesion between similar or dissimilar substrates.

Performance Specifications:

Application of water-based laminate adhesives via direct gravure printing method incorporates a variety of options using patterned anilox rolls. In this process, excess adhesive on the applicator is metered off using a doctor blade. At the same time, one substrate is printed with glue under controlled conditions and then combined with a second layer in the “wet state.” The material composite is then dried and cured through heat and pressure through a series of heated rolls.

Performance Specifications:

Shawmut Corporation

Global Headquarters

208 Manley Street

West Bridgewater, MA 02379

USA

Industries Served

Capabilities

About Us

Brands

More

Legal