In the summer of 2020, Shawmut set out to solve a serious issue that our country faced. COVID-19 exposed significant vulnerabilities in our country’s reliance on overseas health care supply chains. And as a world leader in the production of advanced materials, we knew that we could help solve this problem by bringing N95 particulate respirators manufactured in the USA. Creating another source for the gold standard in filtration mask stateside would help shorten the supply lines, allowing for more rapid and scalable responses to unprecedented needs across the US and industries at-large.

More Than Just Create but Innovate

But solving just for supply wasn’t enough for our team. Like many of us, we had seen the images of the frontline, healthcare, and essential workers with facial indentations and bruising from wearing N95s for extraordinary sessions accompanied by looks of sheer exhaustion. And with those images burned into our minds, we knew that we didn’t want to build just an N95 mask but a better one. So, beyond designing, engineering, and manufacturing N95 masks in our recently revitalized West Bridgewater, MA facility, we wanted to innovate beyond what was already available.

Iterative Development

We leveraged our century of experience in the advanced materials industry to make it happen. Our rapid-development innovation team took the task to heart by thoroughly examining the competition and market leaders’ characteristics. We wanted to know what was critical to making a mask that was superior across all criteria.

It was no easy task. Across the development, in-house testing, and rapid prototyping, we went through no less than 25+ different iterations of shape, nose foam, and elastic. But our engineering team was meticulous and tireless in their pursuit of quality, safety, and comfort. The result: Shawmut’s new ProtexTM N95 Particulate Respirator, which is easier to breathe through thanks to its patent-pending ProtexTM ADCTM All-Day-Comfort System.

More Than N95

What does that mean for users? Our product meets the high-level requirements that users would expect from an N95 mask. Our N95 respirator offers at least 95% filtration and has been certified by NIOSH (TC-84A-9295). And it features a molded cup-style, the gold standard preferred by most N95 users for its performance.

How does the Shawmut N95 respirator exceed expectations? For many, N95s are not comfortable to wear for long periods. Among their chief complaints: difficulty breathing through the filter material, rough and irritating inner shell material, humidity buildup inside the mask, eyeglass fogging, pressure points around the edge of the mask on the nose bridge and cheeks, and excessive tightness around the head. We wanted to address all of these issues when we introduced a new and innovative N95 particulate respirator. So, we measured our success across three paradigms: fit, feel, and function.

Fit, Feel, and Function

For fit and feel, the mask’s foundation is structurally strong and created by custom-engineered thermoform molds designed with crucial feedback from users, including frontline workers, combined with 3D scanning, in-house testing, and rapid prototyping to get a better fit without excessive pressure on the face or skin. Spreading the pressure out evenly relieves the pain points.

We also dialed in inner layer softness for unrivaled comfort compared to market-leading N95 masks. The inside nose foam is a departure from our competitors as well. Our engineers innovated by choosing a high-sealing, slow-recovery viscoelastic nose foam for a secure but comfortable seal that provides a better fit.

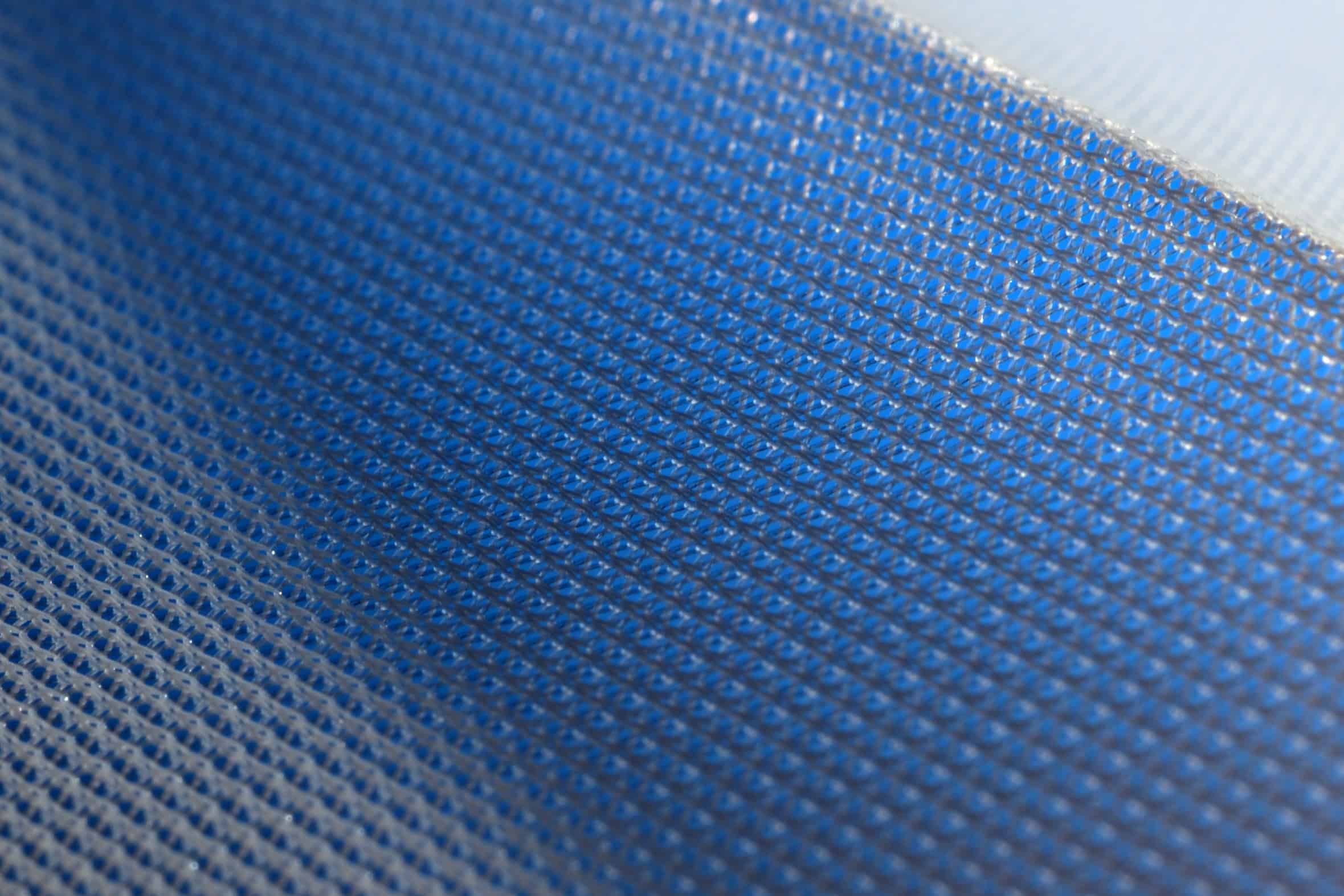

We utilized Shawmut’s proprietary high-quality, bi-layer, melt-blown filtration material made right in our manufacturing plant using new equipment from Germany’s Reifenhäuser REICOFIL GmbH & Co, the world’s most advanced melt-blown filter media production system, for an incredibly lightweight but highly efficient, effective inner filtration layer for function. This multi-layer filter is thinner and lighter while still exceeding N95 standards for filtration. The result? N95 respirator protection with less air resistance, easier breathability, and cooler, fresher air inside the mask.

More Than the Sum of Its Parts

All of these coalesce to create the ProtexTM All-Day-ComfortTM System to deliver cutting-edge comfort, performance, and protection. And to bring this vision to market, we’ve made key executive investments, marketing, and engineering expertise drawn from major PPE, industrial safety, and healthcare companies to deploy this new business unit rapidly.

We are proud of this innovative system as we deliver an American-designed, engineered, and manufactured N95 respirator to market. And we are confident we have the history, design, and manufacturing mastery to continue to make waves in the N95 mask and PPE industry for years to come.